ABOUT OUR STORY

About Our Reputation for Excellence 30 Years in the Making!

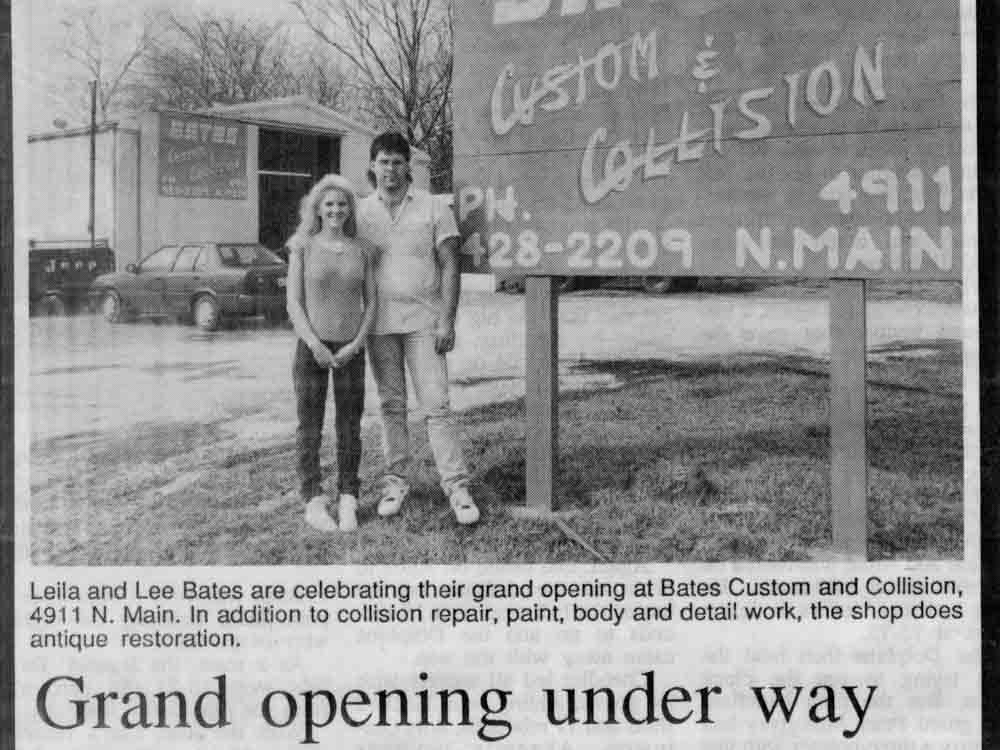

The Bates Collision story begins more than 30 years ago in Baytown, Texas through the vision of Lee Bates, a young repair technician who got his start sweeping floors in a body shop, but had a love for vehicles, developed a real talent for repairing them and knew he could provide a remarkably better repair experience in his hometown.

Since our beginnings in 1990, we have been committed to treating our customers like family; with the highest levels of Quality, Service, Convenience, and Respect available in the collision repair industry. We work hard every day to earn that trust by treating every customer like family (and we’re local, so some of them actually are)!

Below you can learn more about us and see how we got from where we started to where we are today.

Baytown Sun Reader’s Choice Award Winners

Bates Collision Center has been chosen for the Baytown Sun Reader’s Choice Award in 2007, 2009, 2013, 2014, 2015, 2016, 2017, 2018, 2019, 2020, 2022 and 2023.

It means so much to us to be recognized by our customers. Our connection to the Bay Area community has always been so important to us. Click here to read more about our story…

Green Technology

Recycling for the Environment

To Protect the Environment and Employees

Energy Efficiency

“Despite collision shops not being perceived as front runners of the green movement, our dedication to reducing hazardous waste and protecting our environment and our community has always been a priority” says Lee Bates, President-Bates Collision Centers. “We will continue our dedication to be on the cutting edge of eco-friendly technology for collision repair shops.”